We devoted the previous article to the glued installation of vinyl tiles. In this publication, we will consider the features of laying PVC interlocking floors.

Requirements for the premises

Rough work, wall and ceiling finishing must be completed. All openings must be filled with windows and doors. A stable above-zero temperature should be ensured at the facility. It is best to keep it between 18 and 25 degrees. The relative humidity in the room should not exceed the 60% threshold.

Carrier requirements

Cleanliness . It is recommended to sweep and vacuum the base, otherwise the floating floor will “crunch” under your feet. It makes sense to prime a loose screed.

Plane . On the surface, smooth drops of no more than 2 millimeters by 2 meters are allowed . Pronounced local irregularities lead to punching of the coating and increased loads on the locks, so they should be eliminated.

Monolithic screeds, if necessary, level with a leveling compound. And firmly lying tiles and porcelain stoneware are carefully putty at the seams to eliminate grooves and stepped drops.

Strength. Modular vinyl flooring can be squeezed by chair legs if the base is too soft or floating. Therefore, old coatings such as linoleum, vinyl tiles, laminate, cork will have to be removed.

Residual moisture. The maximum hygrometer reading for cement screeds is 2%, for wooden floors 12%.

If the interlocking PVC tiles need to be laid on a wooden floor from a board, it should be reinforced with sheet materials (plywood, OSB, chipboard, etc.) with a thickness of about 10 mm. For this, glue and self-tapping screws are used. If the floor is assembled on wooden beams and sheathed with building boards, the sheathing must necessarily be two-layer with a checkerboard ligation of all joints.

Storage and acclimatization

Before installation, lock vinyl tiles must be brought into the room 48 hours before the start of work and unpacked. It is especially important to observe this rule during the cold season.

You can store PVC tiles only in a horizontal position. Do not place packages on the end. The number of packs in one stack is also limited - details can be found in the manufacturer's instructions.

Required tool

- Rule and measuring wedge for determining irregularities in the plane.

- Construction knife with replaceable blades.

- Metal scissors or guillotine.

- Chopping line or laser builder.

- Joiner's square.

- Polyurethane or rubber hammer.

- Notched trowel (in case of glued installation).

Markup

Laying of PVC tiles can be performed parallel to the length of the room - "deck" pattern. In this case, it is best to place long seams "in the direction of the light." The diagonal installation scheme, as well as the herringbone design, looks spectacular and is very popular now, although there is more waste with such options (up to 10%).

With any stacking pattern, it is very important to determine the location of the first row. For example, with a diagonal installation, you should find and mark the centerline starting line on the floor, and then see how the trimming will turn out in the doorway (so that there are no too small triangles). When laying in parallel, all the rows must be counted so that the width of the trimming tile does not turn out to be less than 50 mm, otherwise the first row should also be trimmed (make it narrower).

Assembly of a free-lying modular covering

Locks located at the ends of PVC tiles, in most cases, allow you to assemble a floating floor without fixing the functional elements of the coating to the base. That is, in this case, the same technology is used as when installing the laminate.

Some manufacturers recommend that you resort to glue installation of interlocking vinyl in cases where increased loads will be applied to the floors.

Glue installation of PVC lock is required:

- If the length of the room is more than 8 meters, or its total area is more than 64 squares.

- If the room is too complex (many corners, columns and other elements).

- If the floor in several rooms is laid with one carpet (without sills).

- If more than half of the area of the room will be filled with furniture.

- In public and commercial areas.

- In the bathrooms (plus the adjoining to the walls is sealed with a sealant).

The use of a substrate for mounting relatively soft tiles is usually not required. However, some modular flooring models are quite rigid, so it is better to use a substrate with them to create a softening damper layer. In this case, specialized materials of small thickness (up to 2 mm) and with increased resistance to compression (more than 400 kPa) are used.

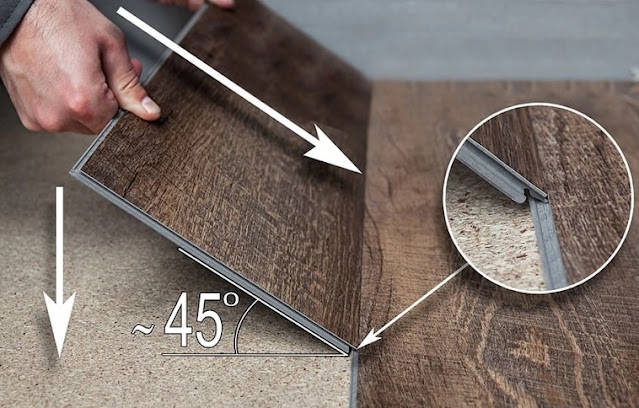

In any case, it is better to start the installation from the corner. The first row of planks is positioned with a groove from the wall orientation. Functional elements are wound into each other by hand, while each next tile is first inserted into the groove of the previous one at an angle of about 25-45 degrees, and then lowers into the plane with a smooth translational movement.

The strips should be connected in locks without gaps, there should be no stepped differences at the joints. In order for all the locks to snap tightly, and the material is completely straightened on the main floor (important for soft models), it is recommended to resort to the use of stitching rollers.

They cut the PVC lock tile with an ordinary construction knife or metal scissors. For this, a square is attached to the bar and an incision is made on the front side. Then the tile is broken and, if necessary, cut from the back side. You can also use a special guillotine.

Soft interlocking tiles are assembled into a single coating without the use of any impact manipulations, however, manufacturers of more rigid vinyl models offer to lightly tap through a "conductor" (for example, made from a piece of tile).

For any installation pattern, it is imperative to tie the transverse seams. To do this, each new row should be started with the remaining tile fragment from the previous row. In this case, the "gap between the seams" should not be less than 25 centimeters.

Around the perimeter of the room and near any stationary elements of the interior, the master must leave a technological gap of about 7-10 mm. It is necessary for the free thermal expansion of the floating floor. The modular PVC access floor can be used immediately after installation.

Read also :

- house elevation design

- small beautiful house

- girls bedrooms designs

- outside colour of indian house

- pictures of kitchen designs with white cabinets