|

| What are the 4 types of welding? |

Welding is an essential process in fabrication, allowing for the seamless joining of materials. There are various methods to achieve these strong connections. Let's dive into the four primary types of welding techniques that professionals utilize to create durable bonds.

What Are The 4 Types Of Welding?

1. MIG Welding (Metal Inert Gas)

|

| What are the 4 types of welding? 1. MIG Welding (Metal Inert Gas) |

MIG welding, also known as Gas Metal Arc Welding (GMAW), is a versatile and widely used technique. It involves melting a consumable wire electrode and fusing it with the base metal. The process is conducted in a protective atmosphere created by an inert gas, often argon or a mix of gases. MIG welding is cherished for its speed and ease of use, making it suitable for both beginners and experienced welders. This method is particularly effective for joining thinner materials, making it prevalent in industries like automotive manufacturing.

2. TIG Welding (Tungsten Inert Gas)

|

| What are the 4 types of welding? 2. TIG Welding (Tungsten Inert Gas) |

TIG welding, or Gas Tungsten Arc Welding (GTAW), is renowned for its precision and the high-quality welds it produces. In TIG welding, a non-consumable tungsten electrode generates the arc that melts the base metal, while a separate filler rod may be added if necessary. The welding area is shielded by an inert gas, often argon, preventing oxidation and ensuring clean welds. Due to its meticulous control and ability to create strong, neat joints, TIG welding is commonly used in aerospace applications and artistic metalwork.

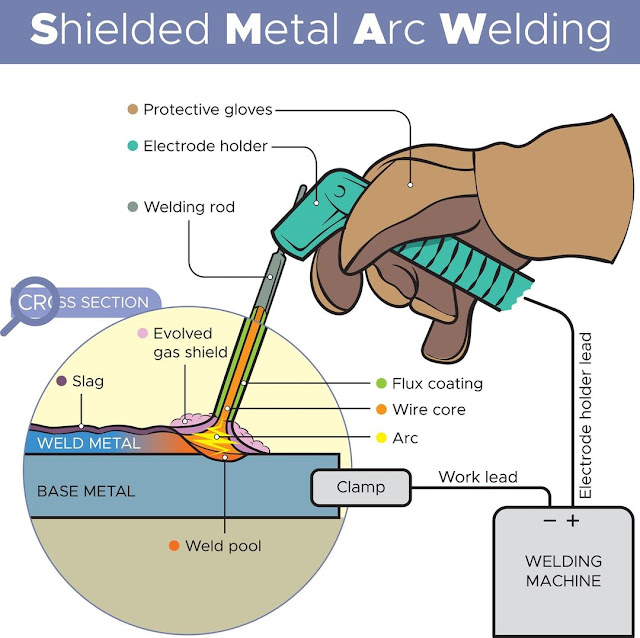

3. Stick Welding (Shielded Metal Arc Welding)

|

| What are the 4 types of welding? 3. Stick Welding (Shielded Metal Arc Welding) |

Stick welding, technically known as Shielded Metal Arc Welding (SMAW), is a classic method dating back decades. It involves using a consumable electrode coated in flux to create the weld joint. As the electrode melts, the flux releases gas that shields the weld from contaminants. Stick welding is known for its versatility, making it suitable for outdoor and on-site projects, even in windy or rainy conditions. This type of welding is frequently used in construction and maintenance work due to its reliability and accessibility. See also: oxy acetylene welding equipment.

4. Flux-Cored Arc Welding

|

| What are the 4 types of welding? 4. Flux-Cored Arc Welding |

Flux-Cored Arc Welding (FCAW) is a variation of MIG welding that offers increased portability and efficiency. Instead of a solid wire, FCAW employs a tubular wire filled with flux. This flux creates a shielding gas when it melts, protecting the weld from atmospheric elements. FCAW is known for its deep penetration, making it ideal for thick materials and heavy-duty applications. It's often preferred in industries such as shipbuilding and structural fabrication.

In conclusion, the world of welding is diverse and multifaceted, with each technique tailored to specific needs. From the speed of MIG welding to the precision of TIG welding, the robustness of stick welding, and the efficiency of flux-cored welding, each method has its place in various industries. Understanding these distinct welding methods empowers professionals to choose the most suitable approach for their projects, ensuring strong and reliable connections every time.

FAQ

What are the 5 basic types of welding?

The 5 basic types of welding include MIG welding, TIG welding, Stick welding, Flux-Cored Arc Welding, and Submerged Arc Welding.

What are the 7 types of welding?

The 7 types of welding encompass MIG welding, TIG welding, Stick welding, Flux-Cored Arc Welding, Submerged Arc Welding, Laser welding, and Electron Beam welding.

What are 4 different types of welding machines?

Four different types of welding machines are MIG welders, TIG welders, Stick welders, and Plasma arc cutters.

What are the 9 types of welding?

The 9 types of welding comprise MIG welding, TIG welding, Stick welding, Flux-Cored Arc Welding, Submerged Arc Welding, Laser welding, Electron Beam welding, Gas Welding, and Resistance welding.

What are the different 12 types of welding?

The different 12 types of welding encompass MIG welding, TIG welding, Stick welding, Flux-Cored Arc Welding, Submerged Arc Welding, Laser welding, Electron Beam welding, Gas Welding, Resistance welding, Plasma Arc welding, Oxy-fuel Welding, and Friction welding.